Busbar processing copper bar bending machine is one of the important equipment in the power equipment and electrical appliance manufacturing industry. It is mainly used for bending busbar copper bars to meet the connection needs of different electrical equipment. The emergence of busbar processing copper bar bending machines has greatly improved the efficiency and accuracy of busbar copper bar processing and made an important contribution to the development of the electrical manufacturing industry.

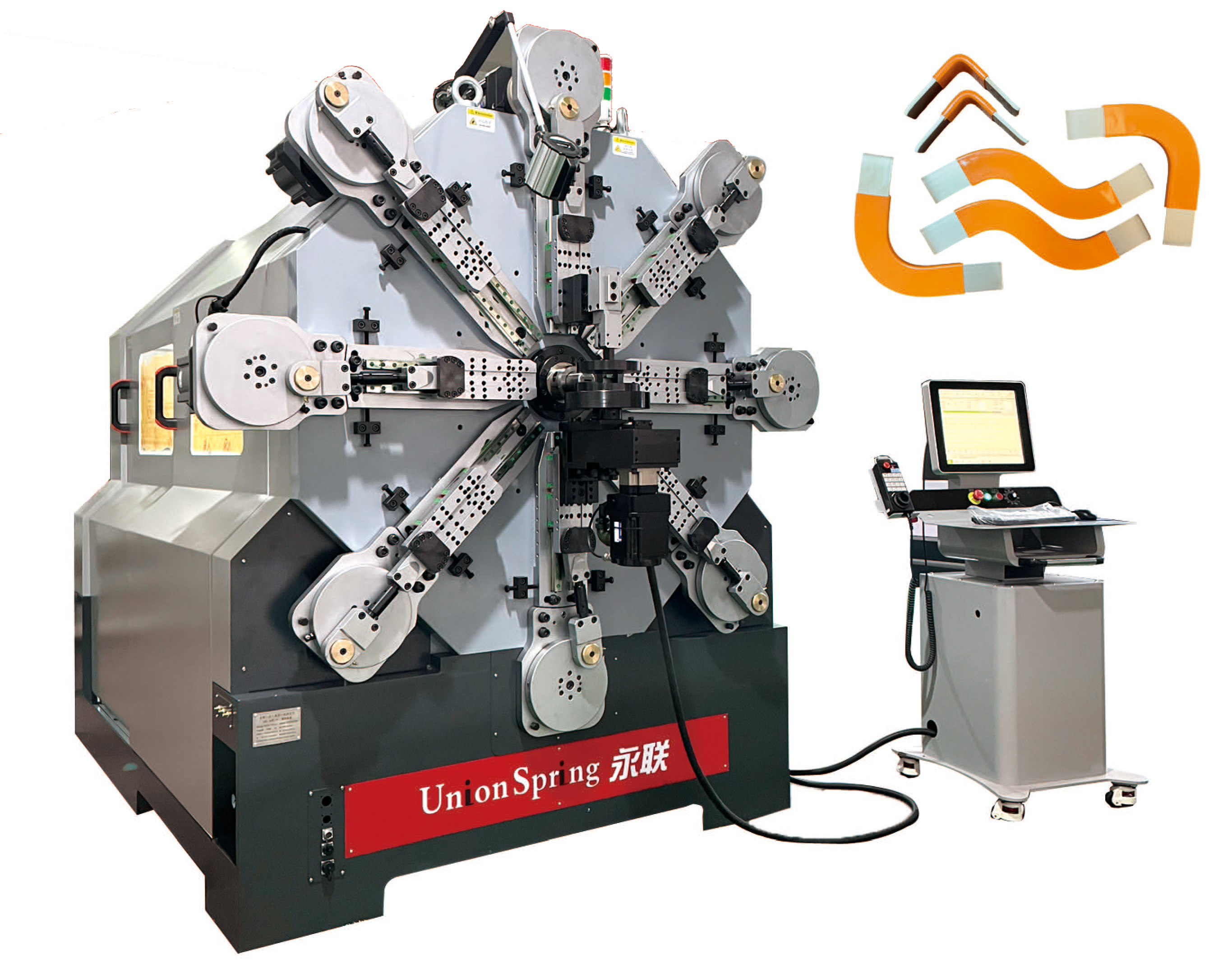

The main features of the busbar processing copper bar bending machine include high precision, high efficiency, high stability, etc. Its working principle is to use mechanical transmission and control systems to cause the copper bar to bend and deform when passing through the bending die, thereby achieving the required shape and angle. During the processing, the busbar processing copper bar bending machine can automatically complete multiple processes such as feeding, positioning, and bending of the copper bar, greatly improving production efficiency and processing accuracy.

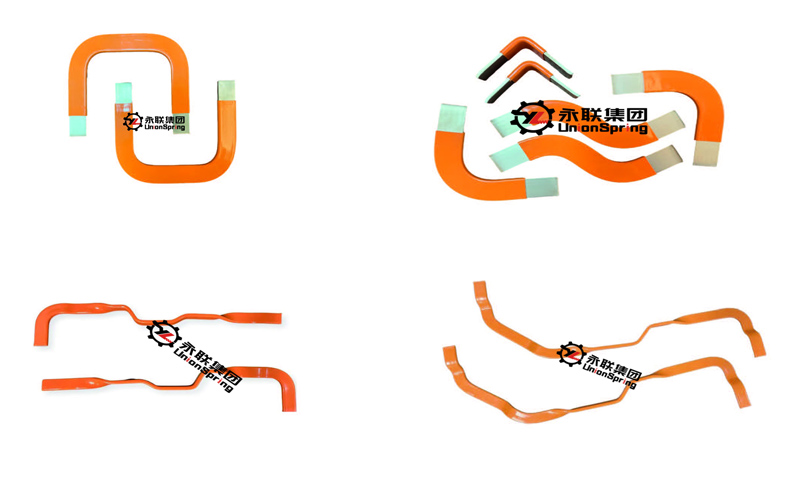

The application fields of busbar processing copper bar bending machines are very wide, including electric power, energy, transportation, construction and other fields. In the power system, busbar processing copper bar bending machines are widely used in substations, power plants and other places to make various busbar connectors and power distribution equipment. In the field of transportation, busbar processing copper bar bending machines are also used to make electrical connectors for railways, subways and other means of transportation. In addition, in the construction field, busbar processing copper bar bending machines are also widely used in electrical installation and maintenance in buildings, shopping malls and other places.

There are some things you need to pay attention to when using the busbar processing copper bar bending machine. First of all, the equipment needs to be comprehensively inspected and debugged before operation to ensure that the equipment is in good working condition. Secondly, during the processing, it is necessary to select the appropriate mold and processing parameters according to the material, thickness and processing requirements of the copper bus. At the same time, attention needs to be paid to the maintenance and upkeep of the equipment, and regular cleaning, lubrication and inspection are required to ensure long-term stable operation of the equipment.

The development trend of busbar processing copper bar bending machines is towards digitalization and intelligence. With the continuous development of industrial Internet technology, the busbar processing copper bar bending machine will be able to interconnect with other equipment in the factory to achieve real-time monitoring and analysis of production data. At the same time, by introducing technologies such as artificial intelligence and machine learning, the busbar processing copper bar bending machine will be able to automatically complete more complex processing tasks and improve production efficiency and processing accuracy.

In addition, the busbar processing copper bar bending machine will continue to innovate in terms of material adaptability, processing accuracy and environmental protection. With the continuous emergence of new materials and new processes, busbar processing copper bar bending machines need to be able to adapt to more types of copper bar materials to meet the needs of different fields. At the same time, processing accuracy and environmental protection are also important directions for the development of busbar processing copper bar bending machines. Through continuous technological innovation and optimization, busbar processing copper bar bending machines will be able to reduce energy consumption and environmental pollution while ensuring processing quality, and achieve sustainable development.

In short, the busbar processing copper bar bending machine, as one of the important equipment in the power equipment and electrical appliance manufacturing industry, has broad application prospects and development space. With the continuous advancement of technology and the continuous expansion of the market, busbar processing copper bar bending machines will continue to improve production efficiency, processing accuracy and environmental protection, and make greater contributions to the development of the electrical manufacturing industry.