Products Description

1. The 3D wire bending machine adopts Taiwan computer control system and Japanese servo motor, which is independently controlled by several sets of servomotors, with powerful expansibility and features of convenient, fast, high speed and high precision.

2. The computer startup and shutdown speed is fast, interface language can switch between Chinese and English, easy to operate.The computer interface can adjust the speed while producing, and the production speed is more than 25% higher than that of domestic counterparts.

3.Bearing, gear, guide rail and other important parts are imported accessories.Protective device anti - collider, composite tool to complete all procedures, quality is guaranteed and lesswearing parts.

4. High precision, can do wire forming products within the range of 3.0-12mm wire diameter, the error is reduced to 0.1mm. The use of the automatic wire feeder allows the machine to change the wire operation more convenient.

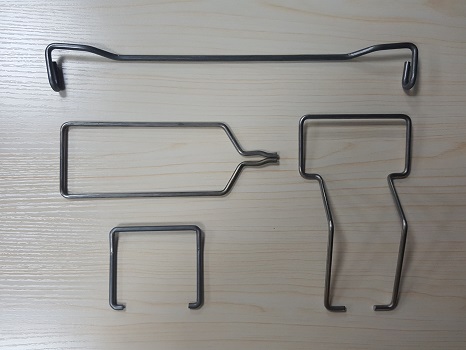

5, The machine is mainly used in the auto parts industry; pet cage accessories; garden tool accessories; electronic and electrical products forming; toy accessories forming; sports equipment accessories forming; kitchen and bathroom pendant hardware forming; handicraft forming; supermarket shelf accessories forming and other types of metal wire forming field.

Technical parameter

Model | US-3D708 | US-3D710 |

Axis | 7 | 7 |

Wire Diameter | 4-8 mm | 5-10 mm |

Wire Wheel Sets | 3 sets | 3 sets |

Wire Feeding Axis | 4.5KW | 4.5KW |

Rotary Wire Axis | 2.0KW | 2.7KW |

Cutting Axis | 2.7KW | 5.5KW |

External Torsion Axis | 2.7KW | 4.5KW |

Internal Torsion Axis | 2.7KW | 5.5KW |

Torsion Head Lift Axis | 1.2KW | 2.0KW |

Platform Lifting Axis | 0.75KW | 1.0KW |

Machine Size | 3400*1400*1700mm3 | 3800*1500*1700mm3 |

Machine Weight | 2400kg | 2600kg |

The specifications and features are subject to change without notice.