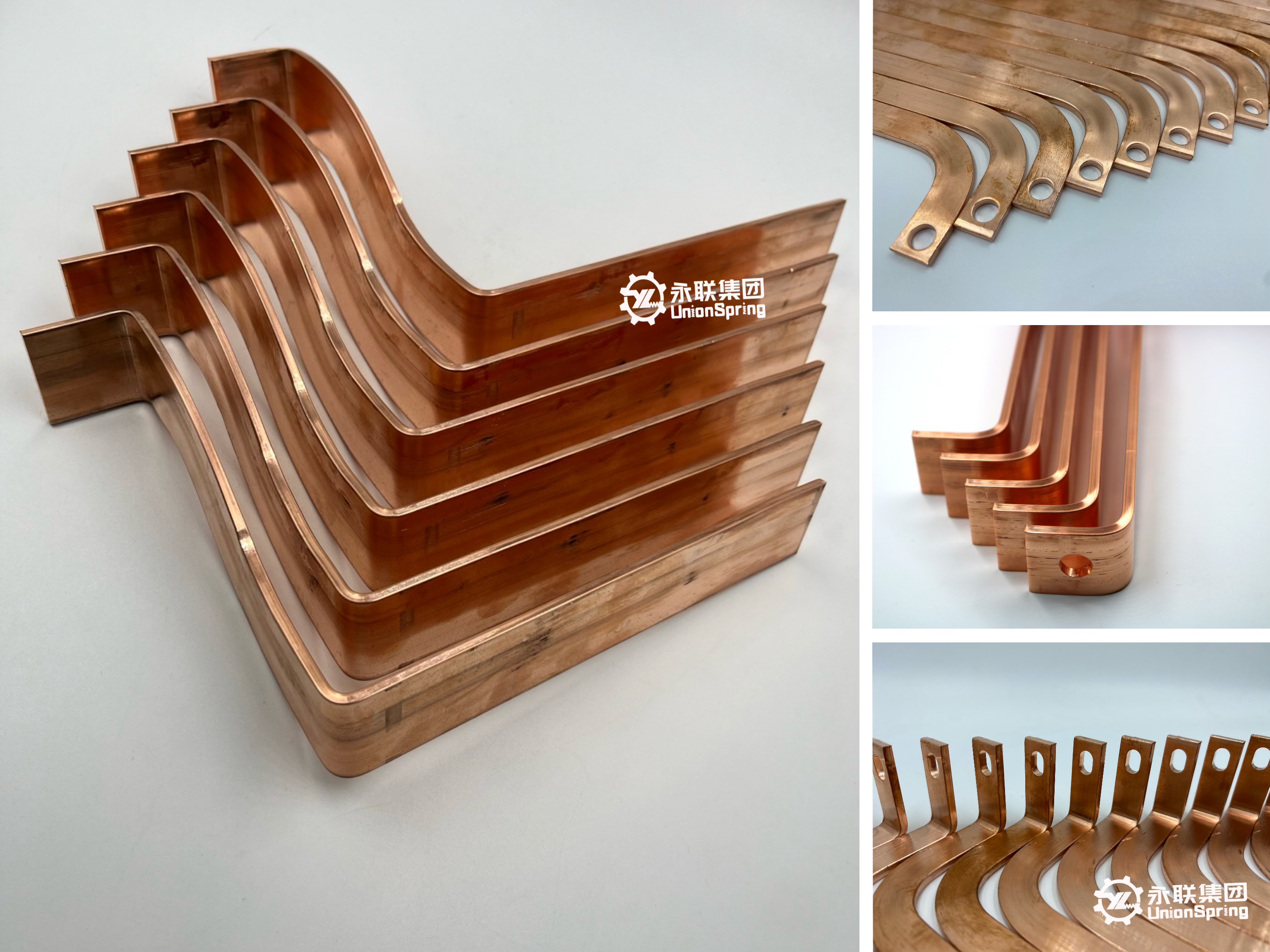

Products Description

The specifications and features are subject to change without notice.

Machine features

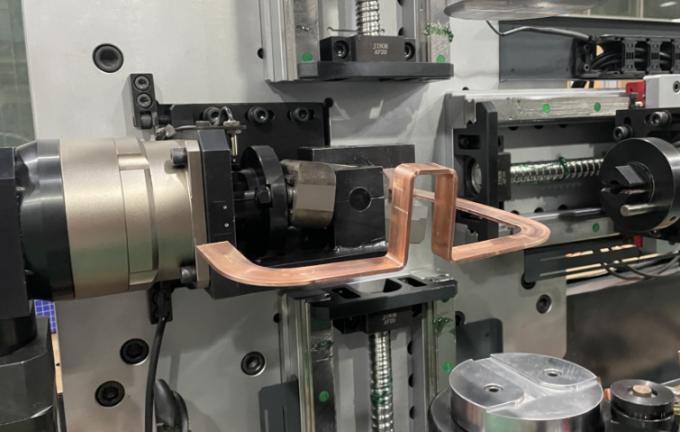

l The machine is equipped with 8 sets of servo motors and has high accuracy. It can achieve an accuracy of ± 0.05mm, and the repeatability of machining accuracy can reach ±0.02 millimeters. It is also equipped with a high-precision encoder to ensure the accuracy of the processed work piece.

l This machine has a high degree of automation. It is equipped with CNC control system, which can accurately process the required size of the product and reduce the labor intensity of the workers. The machine is also equipped with a variety of safety devices, which can effectively prevent any potential safety accidents.

l Copper Busbar Bending, Punching, Cutting Machine is a very advanced equipment with excellent performance. It has high precision, good stability, high degree of automation, and a variety of safety devices. It is suitable for processing copper busbar in electrical equipment manufacturing, power system construction, instrumentation, and other industries.

Machine advantages:

In the world of electrical switchgear and control panels, precision and efficiency are paramount. Our state-of-the-art CNC machines offer a range of benefits that will transform your busbar processing operations:

ü Unmatched Precision: Achieve consistently precise cuts and punches with our CNC machines, ensuring flawless integration of busbars into your electrical assemblies.

ü Enhanced Productivity: Streamline your production workflow with our high-speed CNC capabilities, dramatically reducing processing time and boosting overall efficiency.

ü Reduced Labor Costs: Minimize manual labor requirements and optimize your workforce with our automated CNC solutions, streamlining operations for cost-effective production.

ü Strong Construction: Our machines are built to withstand the demands of industrial environments, ensuring years of reliable performance and peace of mind.

ü User-Friendly Interface: Our intuitive software and user-friendly control panel make operation a breeze.

It is mainly composed of a base, a motor, a reducer, a frequency converter, an induction switch, a relay and electrical components, etc. During use, it keeps the wire feeding speed synchronized with the matching spring coiler.

Technical parameter

Model | US-TP35-6 |

Function | Cutting ,Punching and Bending Busbars |

Processing range | 1.0mm ≤ T ≤ 6.0mm | 6.0mm ≤ W ≤ 35mm |

Bender Molds | Stamping mold, wire wheel, mandrel, cutter, bending mold (Edge Bending Mold, End-Bending Mold) |

Machine controller | Industrial Computer |

Axis | 8 |

Wire Feed Wheel Sets | 3 Sets |

Wire Feeding Motor | 2.7kw |

Forming Axis Motor | 2.0KW×3 |

Spinner Axis Motor | 2.0KW×2 |

Punching Axis Motor | 7.5KW |

Cutter Axis Motor | 2.0KW |

Punching pressure | 7T |

Punching method | Hydraulic Press(Mobil 46 hydraulic oil) |

Voltage | Customizable |

Dimension(LxWxH) | 2600*2000*2100(mm) |

Weight(kg) | 3500kg |