Busbar bending machine is an important industrial equipment and is widely used in various metal processing industries. Its main function is to bend metal sheets as needed to meet various needs in the production process. With the continuous advancement of science and technology and the rapid development of industry, busbar bending machines are also constantly upgraded and improved, providing more efficient and accurate solutions for modern industrial production.

The structure and working principle of the busbar bending machine are relatively simple. It mainly consists of a frame, a workbench, a bending mechanism, a hydraulic system and an electrical control system. The rack is the skeleton of the entire equipment, and the workbench is used to place the metal sheets that need to be bent. The bending mechanism is the core component of the equipment. The power provided by the hydraulic system causes the workbench and the bending die to move relative to each other, thereby realizing the bending of the plate. The electrical control system is responsible for the overall control and operation of the equipment to ensure that the equipment can work according to the preset program.

In practical applications, busbar bending machines have many advantages. First of all, it can achieve high-precision bending and ensure product quality and stability. Secondly, the operation of the equipment is simple and convenient, which can greatly improve production efficiency. In addition, the busbar bending machine also has good versatility and can adapt to the bending needs of metal sheets of different specifications and materials. Finally, the maintenance and upkeep of the equipment is relatively simple, reducing the company's operating costs.

However, the busbar bending machine also has some problems that need attention. First of all, the equipment will produce a certain amount of noise and vibration during the bending process, which may have a certain impact on the working environment and operators. Secondly, the price of equipment is relatively high, which may put some economic pressure on some small businesses. In addition, the operation and maintenance of equipment require professional knowledge and skills, and a certain amount of technical support is required.

In response to these problems, we can take some measures to improve the performance of the busbar bending machine and reduce the cost of use. First, the impact of noise and vibration can be reduced by optimizing the structure and design of the equipment. Secondly, the difficulty of operation and maintenance costs can be reduced by improving the automation and intelligence level of the equipment. In addition, the service life and stability of the equipment can be extended by strengthening equipment maintenance and upkeep.

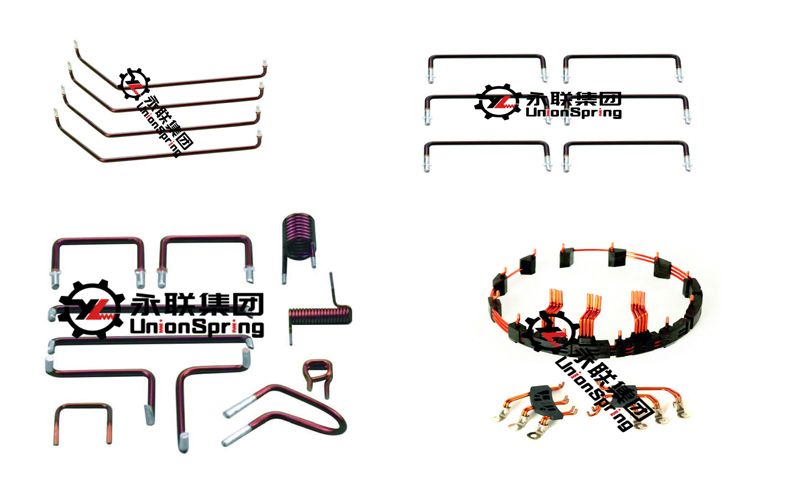

In practical applications, busbar bending machines are widely used in various metal processing industries, such as construction, automobiles, machinery, electronics and other fields. In these industries, busbar bending machines play an important role and provide important support for the production and development of enterprises. For example, in the construction industry, busbar bending machines are used to make various metal components and frames, such as doors, windows, curtain walls, steel structures, etc. In the automotive industry, equipment is used to produce car bodies and various components. In the mechanical and electronic industries, busbar bending machines are used to produce various precision metal parts and components.

In short, the busbar bending machine is an important industrial equipment with wide application prospects and market demand. With the continuous advancement of science and technology and the rapid development of industry, the performance and functions of equipment will continue to be improved and improved, providing more efficient and accurate solutions for modern industrial production.